Success story

Next generation tablet production: 3D Printing

Merck is a leading science and technology company. More than 57,000 employees in 66 countries work on solutions and new technologies for Healthcare, Life Science and Performance Materials.

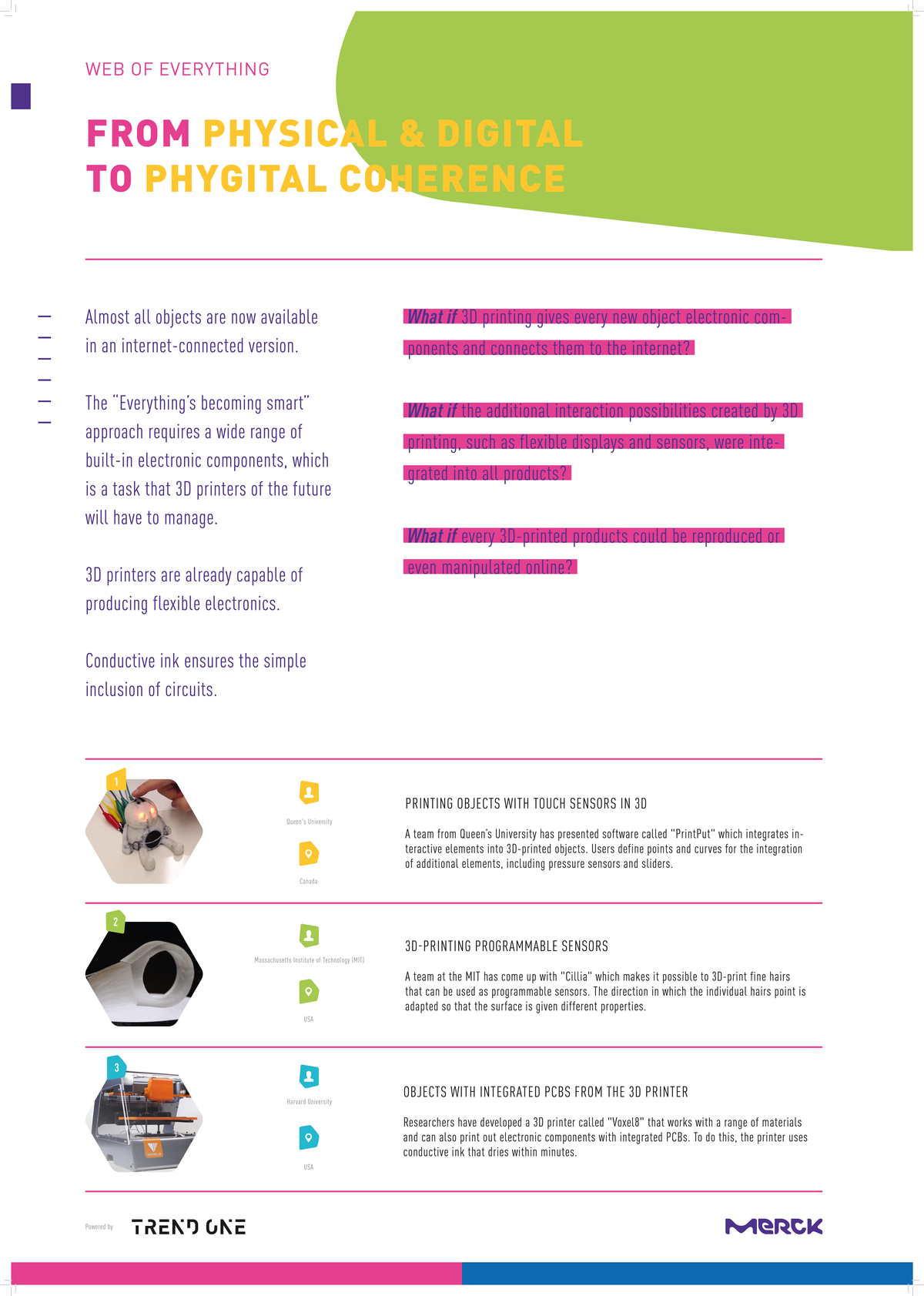

When the 3D printing trend emerged a few years ago, Merck was quick to focus on this novel technology. In order to find opportunities and possibilities for its use, TRENDONE brought visionary impulses from the field of additive manufacturing to Merck in a cross-divisional workshop.